Teleco SHM Systems is a new branch of Teleco active in the development of advanced systems and intelligent sensors for Structural Health Monitoring of buildings and structures and for monitoring transport and aviation systems.

Dynamical structural health monitoring

Civil infrastructures like highways, bridges, civil and industrial buildings, ports, airports, railways, gas and water pipelines, play a role of paramount importance in the social and economic development of countries. These systems are characterized by high costs, high impacts on the quality of life of people and extended operative lives.

The optimal management of these systems requires a careful balance between potentially conflicting requirements like assuring an high safety standard at acceptable costs. It must also be observed that exceptional events like earthquakes, floods or hurricanes can require very critical evaluations concerning the integrity of surviving structures and their exploitation.

Similar problems concern the evaluation of the state of structures whose operative life exceeds the design limits and that of historical buildings endangered by the high level of vibrations due to urban traffic and underground transport systems in many urban contexts.

The relevance of these problems is, in any case, not limited to the evaluation of the integrity of structures potentially damaged by traumatic events; the technologies used in some advanced realizations like, for instance, buildings with active anti-seismic control, require a monitoring of their dynamical behavior extended to their whole operative life.

Structural Health Monitoring (SHM) consists in a set of methodologies that allow characterizing the behavior of physical structures in order to detect possible damages.

It can also be observed that all physical structures undergo, during their operative life, changes due to variations in the physical and geometric properties of materials and in their interconnections with other structures and processes (e.g. variations of the soil characteristics, water infiltrations etc.) that can prejudice their performances.

SHM methodologies are based on the continuous measure of the accelerations in some selected points of the monitored structure by means of sensors operating at a suitable sampling frequency. These measures are then used for identifying dynamical models that can detect deviations of the actual behavior from the reference one. SHM systems can thus detect in real time anomalies much in advance with respect to dangerous situations.

The relevance of SHM methodologies in structure management

The reasons that can suggest the implementation of SHM systems and that have led some countries to enforce specific regulations are the following:

1) Safety. Safety has multiple aspects, concerning both the nature of the considered structure and the circumstances that could lead to damages. In this context a primary role is played, even in absence of abnormal events, by the structures with high social impact. Inside this category we can find the buildings that host public services (in particular schools and hospitals), sport facilities, road and rail bridges, to cite just a few among most relevant examples.

In abnormal situations, like those following an earthquake, monitoring systems allow real-time controls on the maximal accelerations observed in the different parts of a structure and also a comparison of the observed dynamical behavior with the reference one. This allows a fast reuse of non damaged structures and an equally fast exclusion of damaged ones; detailed inspections will thus be reserved to intermediate situations. This can be associated with relevant economic aspects when performed on production facilities.

2) Economical aspects. Private and public administrators are continuously faced with the difficult equilibrium between maintenance costs of the infrastructures and safety requirements. The best results can be obtained by programming the maintenance on the basis of actual needs, evaluated by means of suitable diagnostic tools and, in the case of buildings, this requires a reliable monitoring of their behavior in order to be sure to operate within wide safety margins.

3) Preservation of cultural heritage. This sector must take into account many aspects, often associated with opposite economical valence. On one side, preserving the cultural heritage of a country requires significant investments that, on the other side, contribute to the economic revenues associated with tourism. In this area SHM systems can play different roles: the obvious control of possible deteriorations in order to plan interventions before irreversible damages and the creation of a database containing the descriptions of the dynamical behaviors of the most important structures in order to allow future actions designed with reference to the original characteristics.

The Teleco SHM602 system and its applicability range

Ideal SHM systems should be endowed with robust and economical sensors, perform locally the A/D conversions in order to rely on digital links, be minimally invasive, have a simple installation, make data and models remotely accessible and have a limited cost.

The Teleco SHM602 system, developed in the context of a cooperation between Teleco SpA and the University of Bologna, complies with ISO/DIS 18649 specifications and with the recommendations of the Fib Task Group 5.1. It complies also with the IP67 standard and allows installing the accelerometric and analog acquisition units also in structures subjected to harsh environmental conditions like bridges, industrial plants etc. The SHM602 can thus be used to implement integrated structural and environmental monitoring systems concerning not only civil buildings but also a wide range of other structures without any need of additional protection for the sensors.

These systems can be limited to the acquisition of measures to be used for the analysis of the integrity of the structures or be more general systems that take advantage of the architecture of the system bus and data logger to acquire an extended range of measures. In some cases it could also be useful to exploit the flexibility of the SHM602 even in the realization of monitoring and logging systems that do not concern SHM (e.g. monitoring of heat consumption in large buildings).

Relevant experiences

Systems characterized by various complexity levels have been installed in several civil and industrial environments. This has allowed a comparison of the SHM602 performance in installations concerning buildings operating in a wide range of environmental excitations and in bridges strongly excited by heavy road and railway traffic. Among the more significant applications it is possible to mention Palazzo Saraceni (Bologna), the tower of the Engineering School of Bologna University, some school and industrial buildings and Manhattan Bridge (New York).

Structure and components of the SHM602 system

The SHM602 is an advanced integrated system designed for SHM (Structural Health Monitoring) applications in civil and industrial structures. It is based on the analysis of the response of these structures to environmental excitations (wind, vehicle traffic) or to artificial stimuli (falling weight or other mechanical impulse generators). Differently from traditional systems, usually based on expensive seismic accelerometers and on invasive radial connections with the control unit, the SHM602 relies on digital technologies and on the insertion of the sensors on a bus; the advantages concern cost, reliability and insensitivity to electromagnetic disturbances. The SHM602, that has been developed in the context of a cooperation between Teleco SHM Systems and Bologna University, relies on proprietary algorithms and technologies. It is a modular system whose main components are:

Storage and Control Unit TSD10

- Display: Touch Screen 10”

- Operating temperature: 0°C +70°C

- Operating humidity: 0 – 85% (non condensing)

- Consumption: 12W

- Ports: USB, CF, Ethernet 100Mb, RS232

- Bus: 2 RS485

- Max. number of sensors on every bus: 16@20Hz, 8@40Hz, 4@80Hz

TSM02 sensors

- Operating temperature: -20°C +80°C

- Operating humidity: 0 – 95% (non condensing)

- Environmental protection: IP67

- Acceleration range: ± 1500 mg (two axes)

- Noise: •= 0.32 mg @ 20 Hz

- Temperature measurement range: -20°C +80°C

- Interface: RS485 bus

Analog acquisition unit TGA102

- Two differential inputs

- Gain: 10,100 (TGA102A); 1,2,10,100,200 (TGA102B)

- Resolution: 16 bit (@ 20Hz)

- Input range: ±4.0V (G=1)

- Input offset: ±8.0V

- Max. gain error: 0.15%

- Operating temperature: -20°C +80°C

- Max. error over the temperature range at G=100: 0.004% of the output range/°C

- Max. error over the temperature range at G=100 (bridge configuration): 0.006% of the output range /°C

- Input resistance (dc): 10 GΩ

- Max. input voltage: ±20V

- Max. differential input voltage: ±20V

- Operating humidity: 0 – 95% (non condensing)

- Interface: RS485 bus

TSIC485 – RS485 power insertion and filtering unit

- Operating temperature: -20°C +80°C

- Operating humidity: 0 – 95% (non condensing)

TSBR485 – Signal repeater and auxiliary power insertion unit

- Operating temperature: -20°C +80°C

- Operating humidity: 0 – 95% (non condensing)

- Environmental protection: IP67

Configuration and data acquisition software TBH02

- Sample frequency selection (20/40/80 Hz)

- Start/Stop data acquisition

- Monitoring of acquisition errors

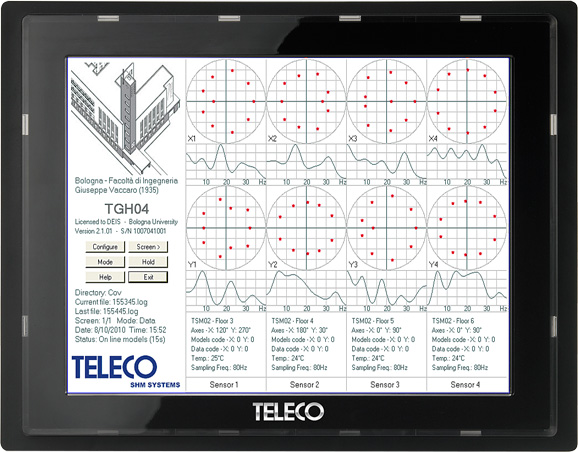

Analysis and visualization software TGH04

- Computation of the power spectrum of the measured signals

- Visualization of the poles of the identified models

- Visualization of the power spectrum of the signals

- Visualization of sensor allocations

- Analysis of the reliability of the models

- Analysis of the suitability of the excitation

Multivariate analysis and diagnosis software TGH06

- Computation and visualization of the power spectrum of the measured signals

- Computation and visualization of the cross-spectra of the measured signals

- Comparison of the power spectra and cross-spectra of the measured signals with the reference ones

- Visualization of sensor allocations

- Reliability analysis of the measured signals

- Diagnosis of abnormal situations

- Generation of alarm messages.

Depliant (PDF)

Specifications (PDF)

Specifications (PDF)